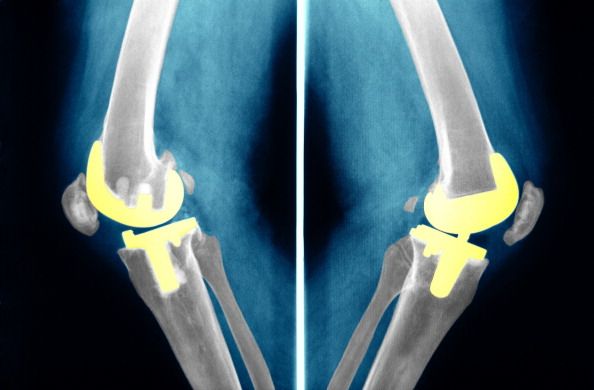

Knees are often the first thing to go. The American Academy of Orthopedic Surgeons predicts that by 2030 total knee replacement surgeries will grow by a stunning 673 percent, with 3.5 million procedures per year. These surgeries are often replacing another knee replacement, which can wear out within five to ten years. That's why a smart knee replacement device could prove to be a crucial innovation in the coming years.

"We are working on a knee implant that has built-in sensors that can monitor how much pressure is being put on the implant so doctors can have a clearer understanding of how much activity is negatively affecting the implant," says assistant professor Sherry Towfighian from Binghamton University in a press statement. Professor Towfighian led a study looking at smart knees funded by the National Institute of Health.

The problem with such an implant would be its power source. If a knee implant had batteries that needed to be replaced, it would require similar surgeries and defeat the entire purpose. To counter the problem, a postdoc in Towfighian's group developed a prototype of an energy harvester that uses the knees own abilities to generate energy.

Developed by Wathiq Ibrahim, the harvester would use what's known as triboelectric energy for power. Triboelectricity realizes itself as small-scale static electricity generated from friction, the type that can be seen when hair rubs against a balloon and the balloon sticks to a wall. The more times two objects are brought together and separated again, the stronger triboelectric effect will occur.

Luckily, knees perform that exact function with every movement.

The team calculated that the smart implant would need 4.6 microwatts of energy to power itself. Luckily, an average walk generates around 6 microwatts. Not a lot, but more than enough for a triboelectric harvester. The sensors powered by the harvest would have a life-changing effect for those using them.

"The sensors will tell us more about the demands that are placed on implants, and with that knowledge, researchers can start to improve the implants even more," Towfighian says.

Robotic body modifications are becoming more advanced. Last year in 15 Ford plants around the world, the car company began outfitting employees in exoskeletons.

Source: Binghamton

David Grossman is a staff writer for PopularMechanics.com. He's previously written for The Verge, Rolling Stone, The New Republic and several other publications. He's based out of Brooklyn.