Researchers at the University of Washington have made 3D printed plastic objects and sensors that can communicate with other Wi-fi devices, despite the fact that they're not even electrified.

“Our goal was to create something that just comes out of your 3D printer at home and can send useful information to other devices,” says Vikram Iyer, co-author of the paper showing the work, in a press statement. “But the big challenge is how do you communicate wirelessly with Wi-Fi using only plastic? That’s something that no one has been able to do before.”

The researchers took inspiration from a decidedly old-school source: mechanical watches. First developed in the 13th century, mechanical watches move without electricity, using intricate gears and springs to keep the hands in motion. Similarly, the UW team replaced some of the functions of electric parts with 3D-printed springs, gears, switches.

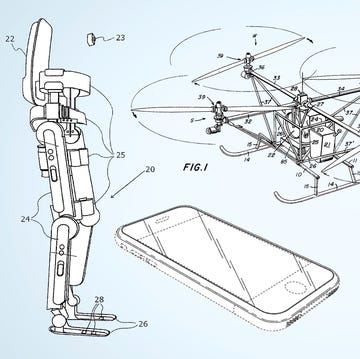

An antenna embedded within the 3D-printed object reflects radio signals sent out by a Wi-Fi router. The antenna then sends the signal to another Wi-Fi receiver in a phone, computer, or any other object. This setup, known as a backscatter system, is activated by physical motion, which triggers the gears and switches inside the 3D-printed object. These gears and switches will turn on and off the antenna's reflective properties, meaning that the object will send a signal only when the user wants.

“As you pour detergent out of a Tide bottle, for instance, the speed at which the gears are turning tells you how much soap is flowing out. The interaction between the 3-D printed switch and antenna wirelessly transmits that data,” says paper author Shyam Gollakota, a UW professor. “Then the receiver can track how much detergent you have left and when it dips below a certain amount, it can automatically send a message to your Amazon app to order more.”

The team printed a variety of objects, from a version of the Utah teapot to buttons, knobs, and sliders that, when activated will send messages. The team was also able to encode static information in 3D printed objects, information that could range from bar codes to instructions for how a robot should handle it while moving.

“It looks like a regular 3D printed object but there’s invisible information inside that can be read with your smartphone,” said co-lead author Justin Chan.

The UW team has released their CAD models so builders can experiment with their work at home. If you're just getting started in 3D printing, or don't know where to start, we've got the guide to get you there.

Source: UW

David Grossman is a staff writer for PopularMechanics.com. He's previously written for The Verge, Rolling Stone, The New Republic and several other publications. He's based out of Brooklyn.