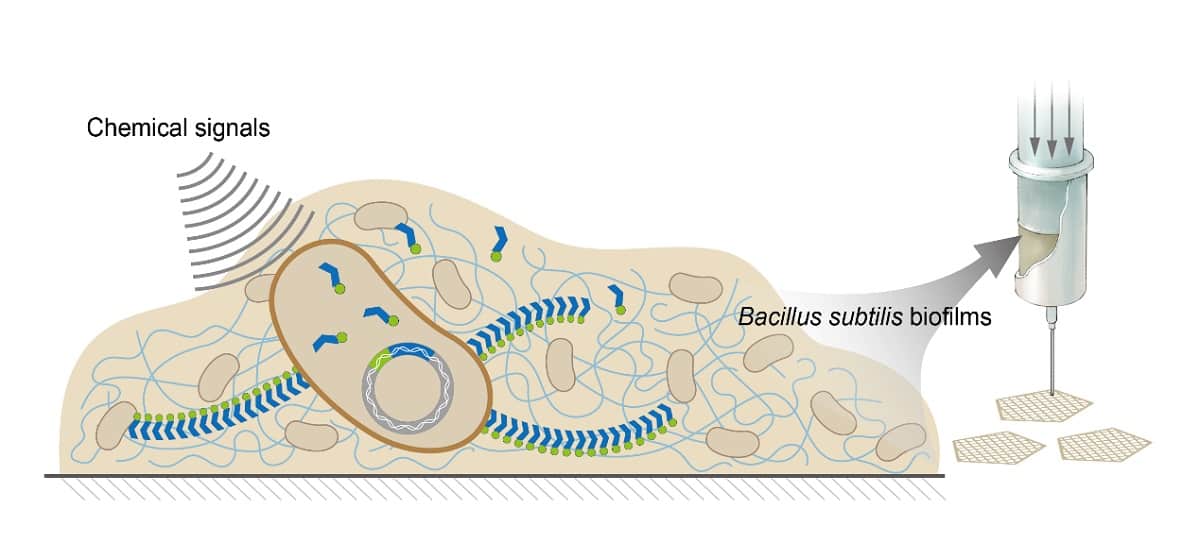

Bacterial biofilms could form the basis of a new biomaterial system with a range of tunable properties from fluorescence to tailored chemical activity. Work by a collaboration of researchers led by Chao Zhong at ShanghaiTech University has exploited the natural secretion of amyloid fibres from the bacterium bacillus subtilis for 3D printing to produce customized nanoscale biomaterials.

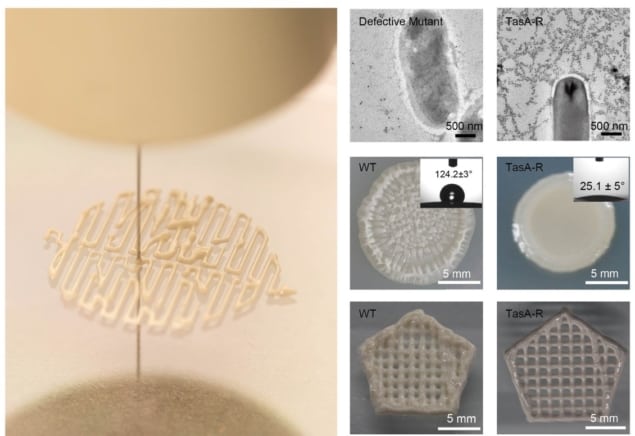

B. subtilis bacteria generate biofilms by secreting amyloid fibres via a tightly controlled cluster of genes known as the tapA-sipW-tasA operon. TapA nucleates the extracellular assembly of TasA proteins to create the amyloid nanofibres that give the biofilm its structural integrity. By genetically modifying the TasA protein, the researchers were able to introduce functional chemical groups onto the TasA fibres excreted by the bacteria. Hence, the bacterial films could be designed to act as functional living materials.

Material properties customized by genetic engineering

In particular, they were able to engineer bacteria to secrete fibres containing enzymatic functional groups into harmless products. They were also able to combine biofilms produced with multiple bacterial strains allowing them to perform a two-step degradation of the pesticide paraoxon, demonstrating the potential for designing eco-friendly and highly efficient functional materials.

In addition to showing the functional capabilities of the biofilms, the researchers then studied their processability as materials. The viscoelastic properties of the biofilms make them ideal for printing. Modifying the functional groups on the secreted enzymes did not hinder the processability of the biofilms and even allowed the researchers to tune their viscoelastic properties for 3D printing applications.

Finally, the authors showed that their living materials could self-regenerate after printing and sustain their initial printing shape as well as their viscoelastic and functional properties. Furthermore, the bacteria could incorporate onto their fibres without affecting biofilm growth or cell viability. They remain viable for five weeks without supplemental nutrition making them ideally suited for many applications.

Full details of the research are reported in Nature Chemical Biology