Robot Can Detect Gas Pipe Leaks

July 18, 2014

In more than one US location gas pipes under city streets have exploded, causing damage and even death. Aging, failing underground pipes carrying natural gas can be notoriously difficult to troubleshoot. Now, a self-propelled robot developed by MIT researchers promises to detect leaks quickly and accurately.

The most recent gas pipe explosion happened in New York City in March, where eight people died in two apartment buildings when a 127-year-old gas main exploded. Closer to home for me was the notorious -- at least in California -- explosion in the City of San Bruno, south of San Francisco, in 2010. Eight people also died there, and the explosion destroyed 38 homes.

Researchers at MIT and King Fahd University of Petroleum and Minerals in Saudi Arabia say their prototype robotic system can detect very small leaks of 1 mm to 2 mm and at lower pressures. Existing leak detection methods tend to be slow and incapable of finding small leaks. They usually involve either leak detectors located inside pipes that use cameras for visual inspection, or acoustic sensors above ground that detect characteristic sound and vibration patterns. Other methods include hydrostatic or liquid natural gas testing and aerial patrols equipped with lasers.

Acoustic tests work best in metal pipes, but not plastic ones, since the material tends to dissipate sound quickly, said MIT chemical engineering doctoral student Dimitrios Chatzigeorgiou, lead author of an article in IEEE/ASME Transactions in Mechatronics that describes the team's results. This method also requires expert operators to do a lot of walking around above ground, and is therefore intermittent. In contrast, the team's robot moves at 3 mph through a pipe and is almost entirely automated. A network of them could conduct ongoing, nonstop monitoring. It can also find leaks in water and petroleum pipelines, and the team says it is talking to gas and water utilities for field testing.

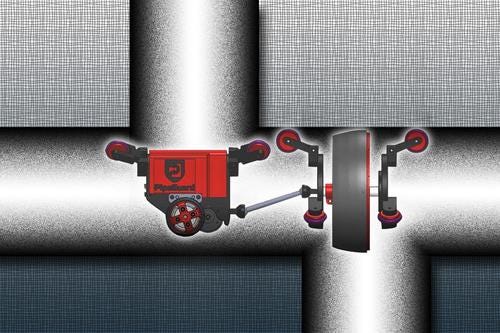

The system detects leaks by sensing a pressure gradient near a leak in the pipe using force-resistive sensors. The small robot has wheels to propel it through a gas pipe. A drum-shaped projection from the robot's body houses a membrane that forms a seal across the pipe's diameter. Liquid flows in the direction of a leak and pulls the membrane slightly toward it. This creates a distortion detected by the sensors, and their data is sent back using wireless communications. The system can detect leaks quickly and pinpoint their location. The robot can potentially go faster than 3 mph, a limit set by motor speed, not sensor speed.

Better detection methods are definitely needed for the hundreds of miles of aging gas pipes in major metropolitan areas. The aftermath of the San Bruno explosion alone has had far-reaching consequences in the region. Not only the utility -- Pacific Gas & Electric (PG&E) -- but also the state agency responsible for regulating it -- the California Public Utilities Commission (CPUC) -- have come under intense scrutiny and widespread criticism for failure to maintain the pipelines, and for failure to ensure that such maintenance was being carried out.

A state senator accused the CPUC of a cover-up. A recent audit of the agency uncovered multi-million-dollar budgeting errors. The National Transportation Safety Board criticized PG&E itself for failing to check the line properly during installation and for the lack of an adequate system to detect failing pipes. More recently, the City of San Bruno sued the CPUC, and the agency's chairman was replaced. It's a big mess, and one that might have been avoided with better robotic leak detection technology.

Related posts:

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)