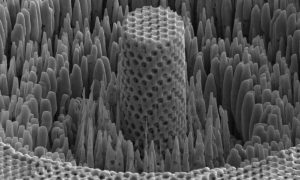

‘High strength metallic wood from nanostructured nickel inverse opal materials‘ describes a material whose strength comes from nickel struts (as narrow as 17nm) whose local yield strength is 8GPa – 4x that of bulk nickel.

According to the paper, which is available in full free, by varying the fine geometry, strength in the final material can be 90-880MPa, modulus between 14-116GPa and density from 880 to 14,500kg/m3.

It has been long realised that imperfect crystals keep real metals away from their theoretical best – something the construction technique chosen for this nickel goes some way to improving.

The team, from the Universities of Pennsylvania, Illinois at Urbana-Champaign and Cambridge, starts with a suspension of plastic spheres a few hundred nm across, suspended in water.

Done in the right way, evaporating the water allows the spheres to stack neatly, and it is this stack that is used as a frame on which to deposit nickel by electroplating. Solvent then removes the plastic, leaving hollows (~70% by volume) and struts.

Done in the right way, evaporating the water allows the spheres to stack neatly, and it is this stack that is used as a frame on which to deposit nickel by electroplating. Solvent then removes the plastic, leaving hollows (~70% by volume) and struts.

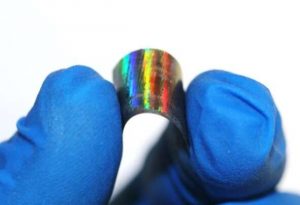

“We’ve made foils of this that are on the order of a square centimeter (on plastic, see photo),” said Pennsylvania researcher James Pikul. “To give you a sense of scale, there are about 1 billion nickel struts in a piece that size.”

While none of the materials involved are particularly expensive, the team recognises that they cannot yet make enough of this stuff for basic mechanical testing, let alone make it on a scale useful outside science.

“We don’t know, for example, whether it would dent like metal or shatter like glass.” said Pikul.

“We don’t know, for example, whether it would dent like metal or shatter like glass.” said Pikul.

If it can be made, and is robust, the sponge-like structure is being mooted as battery electrode material and other uses that can make use of all the space inside.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News